Officine Zoppelletto Srl extends its offerings beyond cutting and bending, offering a range of additional processes that complete the production cycle of sheet metal working.

These services are designed to provide our clients with integral solutions, from material preparation to final treatments, always ensuring high quality and precise results.

Calendering

We offer calendering services for machining parts up to 3 meters wide and 60 mm thick, including the ability to perform conical bending.

This process allows for precisely curved components, meeting specific design and functional requirements.

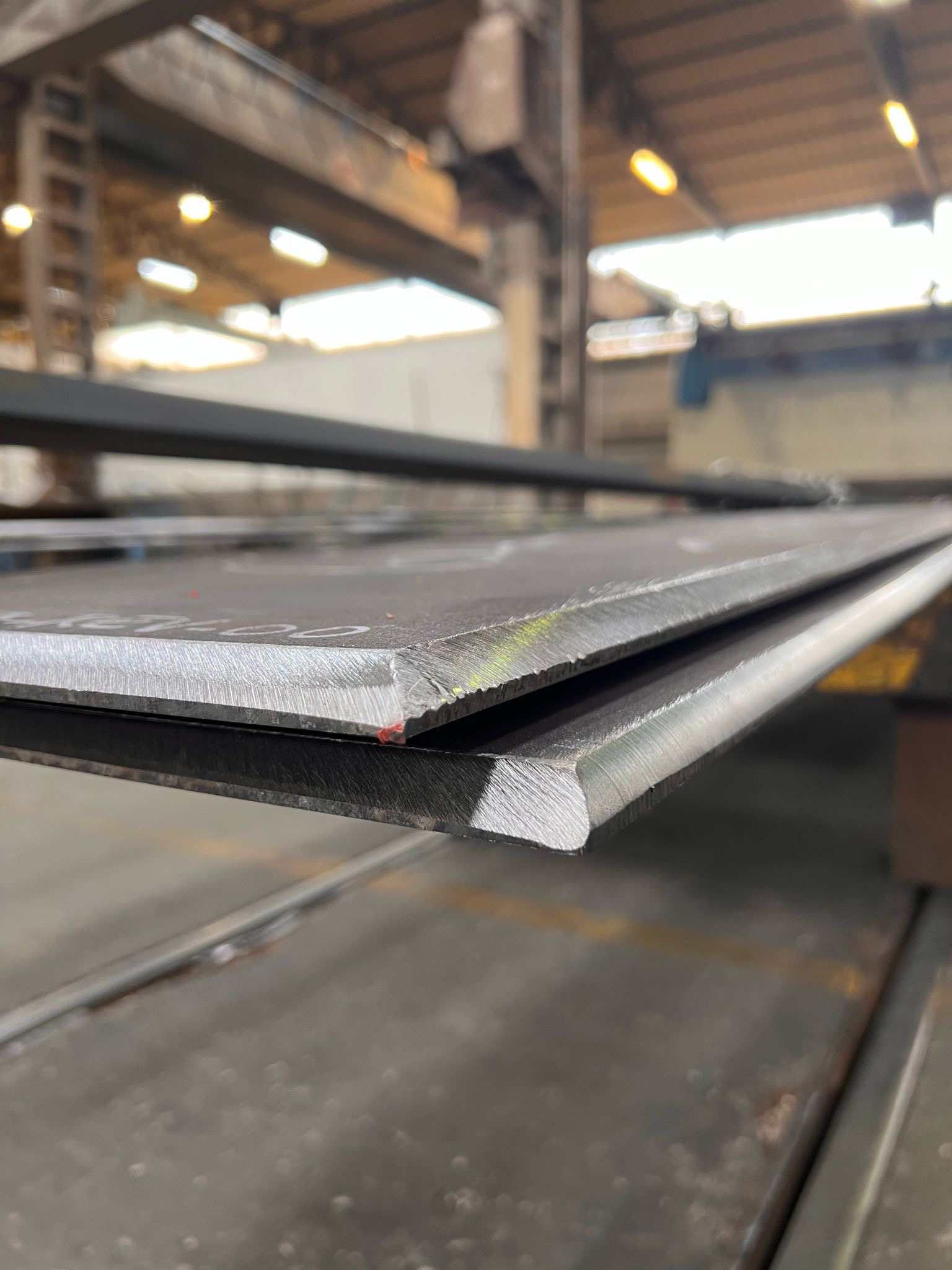

Chamfering

Beveling in preparation for welding is essential to ensure quality joints between components.

Our capabilities include beveling on iron semis at various angles, using advanced techniques such as Bevel plasma cutting and oxyfuel cutting, to ensure optimal preparation for welding.

Welding

We are equipped to perform welding of metal structures according to drawings provided by customers.

This service allows components to be assembled with precision, ensuring maximum strength and integrity of welded structures, in line with design requirements.

Painting, galvanizing and sandblasting

In collaborazione con partner esterni selezionati, offriamo trattamenti superficiali quali la verniciatura, la zincatura e la sabbiatura.

These processes improve the aesthetics and increase the durability of treated components by protecting them from weathering and corrosion, thus ensuring a high-quality finish and increased durability.

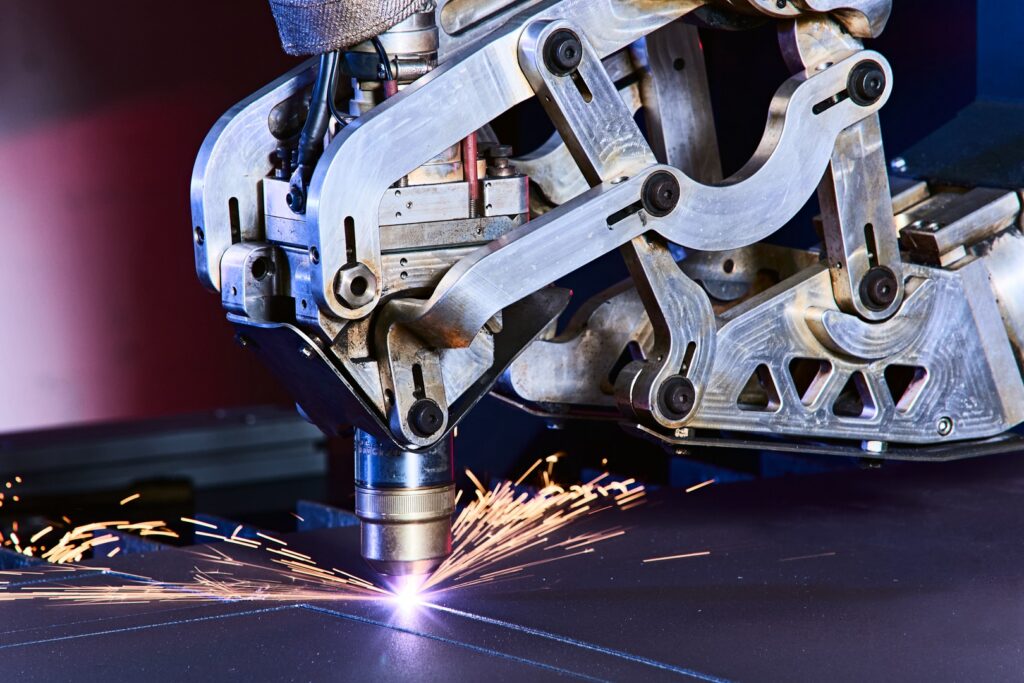

CNC machining

Le nostre lavorazioni meccaniche a controllo numerico (CNC) rappresentano la soluzione ideale per la realizzazione di componenti di precisione.

Using CNC technology, we are able to perform complex machining with high standards of precision and repeatability, effectively meeting a wide variety of design requirements.