We are proud to announce a major new investment that has enabled us to innovate our production processes: the arrival of two new LVD hydraulic press brakes, a true technological revolution that significantly expands our production capacity.

Innovation and Power: A Winning Combination

The two new presses, which exert a power of 2,500 tons, are capable of bending parts up to 13 meters in length. This will enable large-scale machining, thus opening the way to new markets.

In addition, through LVD software, the bending sequence can be simulated, thus verifying the feasibility of the parts to be produced, significantly shortening production and customer response times.

Tandem Technology for Superior Performance

The two LVD synchronized hydraulic benders have a length of 6.6 m x 1250 tons each. They can work together in tandem mode, that is, as if it were a single machine, ensuring perfect bending for the entire length required.

The compensation table provides a concentrated load capacity of more than 400 tons/meter to deform high-strength or very thick materials.

Bend Angle Control: Versatility and Precision

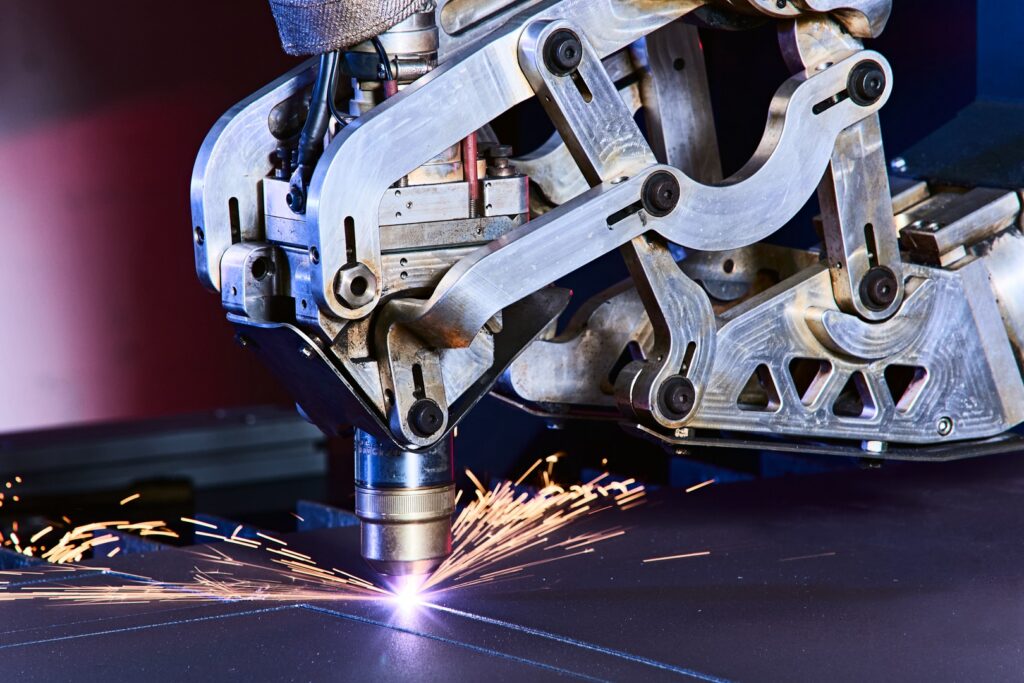

The presses are equipped with a laser camera bending angle control system (LVD patent) that allows for accuracy and repeatability on parts. This advanced technology allows the piston position to be instantly controlled and corrected, ensuring that a perfect bend is achieved without manual control by operators. This is especially important for materials with very large spring returns such as Hardox, Weldox or Streng, where the fold must be done properly on the first shot without subsequent reshoots.

A Future #Future.

This investment reflects our ongoing commitment to innovation and quality, propelling the company into the future as we strive to offer our customers state-of-the-art solutions.

This new expansion of our machine fleet not only enhances our service offerings, but also consolidates our position in the sheet metal processing industry.